Level: Apprentice

Reading Time: 13 minutes

I am roasting to reduce acidity and boost chocolate flavor: I use a 3k drum coffee roaster. Would you recommend roasting a bit longer or hotter maybe 25 minutes building up to 290 degrees? For the Ugandan I've been enjoying a 21 min roast at 275 tops.

Speaking quite generally I don't roast to reduce acidity. If a bean is too acidic for your tastes, don't use it. Any successful roast profile that develops flavor will naturally reduce acidity. It is just the nature of roasting. Profile drum roasting at least.

That said, we (meaning I and those I hope to come along) are stepping out of thinking of the roast as one parameter and discussing it as ‘a bit longer or hotter’. 25 minutes up to 290 F just doesn't say enough about the roast. Oh, and I would never take a bean to 290 F. If I said that in the past, I was less informed than I am now. 275 F is a very good top limit.

I previously laid out the four phases of a roasting profile as I use them.

I find adjusting the Development phase has the greatest impact on developing chocolate and fruit flavors.

That phase occurs from a bean temperature of 212 -232 F and lasts 2.5 - 5 minutes.

If you want to begin to understand why I give that range, keep reading. Otherwise just keep it to about 3-4 minutes and you will be fine.

Once you start getting a handle on it and begin to see the patterns you can do something really exciting.

You can start to design and implement the flavor profile you want in your chocolate.

I’ve been roasting coffee for since 2000. During that time I encountered the term momentum quite a bit. It has clearly influenced how I roast cocoa. In coffee you very much are concerned about keeping the roast both in control, moving briskly forward but not powering ahead like a charging bull. You build a momentum to the roast and in doing so you seem to build a pressure inside the bean. This is both a literal and figurative pressure.

The literal nature shows in an aggressive first crack (don’t forget we are talking coffee here).

The figurative nature is in the form of chemical reactions. We often talked about pushing the roast to develop flavors. But here is the subtle point. Pushing this area of the profile does not in of itself give you flavor. It gives you working material that develop, in the Finishing phase, into flavors.

The same seems to hold true with cocoa. Let’s take three similar but different profiles. This is for a chocolate and fruit prominent Tanzania. To remind you, you read these profiles as Drying time / Development time / Finishing time @ EOR

Profile 1 – xx/3/5 @ 254 F

Profile 2 – xx/7.5/5 @ 253 F

Profile 3 – xx/5/5 @ 254 F

And to keep the amount of data from becoming overwhelming, I’ve left out the drying phase since it does not play directly into flavor development.

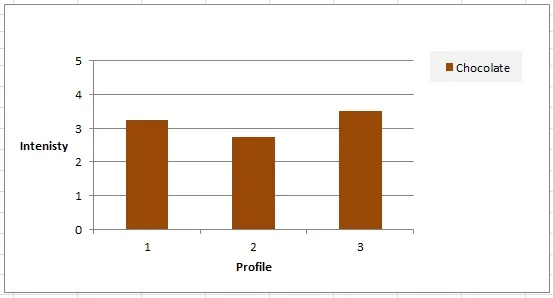

I matched both the Finishing time and the EOR changing only the Development phase. As far as chocolate goes, these are my ratings for the chocolate level.

Notice how they don’t change a huge amount. Roasting can only bring out what is there. If a bean doesn’t have the option for a lot of chocolate (or acidity or fruitiness, etc) nothing you do can make it appear. Always keep that in mind. And the corollary to that is that it is always easier to destroy than create.

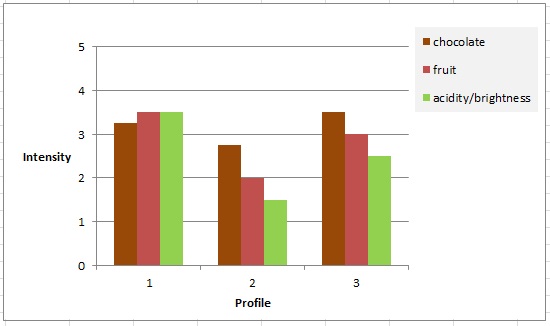

So, Profile 3 has the highest chocolate. But that isn’t the whole story. If it were, you could just pick Profile 3 and be done with it. Look what happens with acidity and fruit.

You say you want lower acidity, so now you pick profile 2. But it really begs the question what do you mean that you want to “reduce the acidity”? I think you mean you don’t want acidity from over powering the profile. And that is completely understandable. I’m making this point to make you think about what you want.

Acidity is not evil. Too much acidity might be evil depending on your tastes. The same can be said for spice in food. I love hot food. For some people with no tolerance for heat, heat is evil. For me, you can’t make it hot enough. In chocolate I’m not a fan of pithy astringency. I’ve met people who adore it.

Let’s talk about those acidity and fruit levels. Again, you might be tempted to pick Profile 2 because it has the lowest acidity. But flavors or more specifically our perceptions of flavors don’t exist in a vacuum. And numbers don’t tell the whole story. Their relationship to each other is critical.

I’m honestly not sure if profile 2 has a lower acidity or it just seems like it does because as it happens, the bitterness in profile 2 is much higher than the other two.

The bitterness punches through and masks other flavors (just like spice in food does for some people). See that little pattern? As the bitterness goes up, the perceived acidity goes down…..or is it the other way around? I actually have data saying it is the bitterness going up, but without extra data it is difficult to tell.

So while we are pulling this all apart, I want to point out one more relationship. Look again at the acidity and fruit levels. Profiles 1 and 3 have a lot of fruit and acid. Speaking from a taste perspective, both of these chocolates taste good. They are full flavored. The big fruit is balanced by the high acid. The acid has given the chocolate a backbone. Without the acid the chocolate could well taste flabby. This is just reiterating one component (acid) isn’t to be avoided. It is part of a whole and critical for balance.

In the case of these three chocolate, profile 2 was the least dynamic. The really long Development phase (outside the 2.5-5 minute window) where there was no pressure developed just fell flat. That is a common trend of no pressure. Lower flavor. I don’t know if it is baked out or the needed compounds are not formed to later be used in the Finishing phase but the result is the same. You need to push the Development phase to develop flavor.

How much? It depends on the bean and YOUR goals. Here are some very general trends I have found regarding the timing of the Development phase.

· Shorter time / faster ramps develop fruit and chocolate flavors. Acidity may appear reduced but is often unchanged.

· Longer times / slower ramps decrease inherent acidity and astringency. Inherent bitterness is unaffected.

· Very short / fast ramps can create bitterness and astringency (roast defect)

· Very long/slow ramps can decrease the entire flavor profile (no pressure)

Noting I suggest 2.5-5 minutes, chocolate develops naturally here. This is why all the levels were very similar. It’s perception on the other hand is affected by what else is created. Profile 1 comes across as having less chocolate only because the fruit and acid are higher and out competing it. In passing these chocolates around, there was a pretty even split between people preferring 1 or 3. No one preferred 2.

Did you catch I tossed in the term roast defect above? The most common one comes from applying too much heat too fast. Basically you are scorching the edges of the bean and it comes through as sort of a metallic or sharp tang. It is surprisingly hard to describe to you here since you can have metallic tastes and sharp tangs in beans that are desirable and not a result of defects. Once you taste it though it is memorable and the key is that it is unpleasant and distinct.

The lucky part though is that it if you think it is there, it is pretty easy to identify by looking at the profile. What does it look like? It is nothing more than a radical increase in the ramp.

I mentioned in the Drying Phase post that the only job of the dialing in your Drying phase is to nail your momentum phase.

If the drying phase is 5 F/min and your 6 F/min you have to really apply the heat to increase your ramp. That extra application of heat can cause a roast defect. This is the exact reason I recommend coming in fast (8-10 F/min) and then slowing down to 6-8 F/min. It is always easier to slow down than speed up.

And once you know the conditions that cause it, you can identify them on the fly while roasting and turn the power down in your roaster (and next time come in faster do you don’t have speed up on the fly). This is how I know how fast to push this phase…by smell. If you are applying too much heat your beans can smell acrid, nearly like they are burning.

Alright. Some final rules of thumb.

Keep the ramp progressing from 212 F to 232 F as quick as you can. This will accomplish a reduced acidity, and boosted or properly developed fruit and chocolate. The conditions to that are 2 though.

1) Don't push so hard you scorch the beans. Take at least 2 minutes. 2.5-3.5 is a safe zone. More than 5 and you may find the chocolate may decline. It will be there, just not accentuated.

2) Don't push so hard that you can't slow the roast down in control from 232-EOR or you are in for roast defects in the next stage.

Chocolate flavors are a balancing act. Parts go up, others go down. It is basically impossible to change only one flavor at a time.

Sometime in the next few weeks we will finish this up with the Finishing phase.

Making your own chocolate? have questions about any step of the process? Why not Ask The Alchemist? He regularly answers reader questions (over 300 answers are waiting for you, maybe he answered your question already) and we've just launched the new ATA video series where he demonstrates the real world answers to your chocolate making questions!