If I read roasting temperature suggestions here, are they referring to environmental temperatures (ET) or bean temperatures (BT), so indicating air temperature above the beans or approximation of the product temperature? For sure the temperatures stated around tempering are referring to product temperatures. But what about those roasting temperatures?

Even if those temperatures would indicate ET at charge time, they feel quite high to me as in other sources I am reading of temperatures (ET or BT?) in cocoa roasting should not exceed 300F to avoid those burned notes.

Being aware that absolute temperatures depend on machine, probe placement and measuring equipment, I charged my last batch at ET=170C (338F) and BT=138C (280F), quickly falling to ET=150C (300F) and below and never exceeding and BT rising to and stabilizing at 125C (257F) after the initial drop. It turned out quite nice, taste wise. Would those temperatures be too low for a proper debacterilization?

Let’s get the easy stuff out of the way. Yes, those temperatures are indeed the level you would roast coffee at. But I am not suggestion you roast as you would coffee. Your confusion actually makes for a great point. Unless an author tells you what they mean, you really don’t know. Whether it is ET or BT. Most of the time, it is ET as that is how oven are controlled. But it sometimes switches to BT to indicate an ending surface bean temperature. Ok, so that was not very easy or clear, or at least helpful. What it really does is illustrate just how difficult it is to roast ‘by the numbers’ when everyone is using different equipment.

The other easy stuff. In theory, your roasting should be a fine kill step (debacterillization) but roasts rarely (if ever) stabilize at one temperature, so when you say that, it’s hard for me to know what you mean.

So let’s back up a little, and walk through a roast. It’s all about differences in temperature and how you use those and that information.

Charging temperature. Basically this is mostly hot air. Really. I don’t mean it is not important. I mean you are reading an air temperature. And there is not a lot of energy in hot air. It’s the reason you can stick your hand in a 500 F oven and not be hurt. It’s all hot air. So I guess I do mean it’s not really important. At least as a really critical ‘target’ temperature. It, like many other temperatures, are just indicators for other things. Why do we pre-heat our roasters and ovens? It’s so we are not wasting time and energy heating up the surrounding material. It’s so we can get down to the business of roasting. It’s why you pre-heat a grill or a pan. It’s to get the process moving. Nothing more, nothing less. And that air temperature isn’t meaningful as the AIR does not contribute much of anything to the roast. But what is does do is tell you the walls of your roaster/oven are HOT and when we put our beans in, we can get right down to roasting. That’s all. And remember, that air temperature is going to be hotter than the walls. As an example, if the air is 400 F, then the surfaces are going to be something substantially less. 300? 350? And as soon as we load the beans, that horribly hot (sarcasm there) air is going to drop, both through heat lost through the opening and as it goes into the beans and suddenly you will see it is barely above the temperature of the room temperature beans. And with that temperature drop, you are miraculously (and significantly) out of the dreaded “over 300 F” range (which is by no means a hard and fast rule). And I mean seriously out. My average drops are to the low 100’s. It frankly can’t be any other way.

On a quick side note, that you say you drop to a ET of only 300 F and your BT is 280 F…something seems really wrong there. There isn’t any way for the beans to get that hot that quickly. That is an end of roast temperature. It seems obvious to me there is some measurement error there. But it illustrates how hard it is to give a couple temperatures to characterize a roasting profile. Also, you mention that my charging temperature is like coffee. Right you are. Charging temperature only affects the start of the roast. It has almost no effect on the rest of the roast. And I start my coffee and cocoa exactly the same because I am roasting them both.

I said I wanted to walk you through a roast, as I see it. And it doesn’t matter if it’s in a drum roaster, a standard or convection oven, on your stove top (now that’s a real challenge) or some other way. For me it’s all about the delta. In many physics and chemistry equations you have two things you are comparing. Often it’s energy. Or pressure. Or temperature. It’s just a way to describe the difference in two numbers. You are stationary in your car. Now you are going 60 mph. The delta is 60. You were going 20 mph and again you are going 60 mph. The delta is 40 mph. Got it? I know you would. Oh, and why ‘delta’. It’s just the agreed upon symbol. The Greek letter d – for difference. Nothing mysterious there. It’s important here because it lets you think through a roast and how to adjust it no matter the setting. The key is this. And it’s something you already know intuitively. The hotter something is compared to something else, the faster the cooler object will heat up. To rephrase, the greater the delta, the faster something heats up. In roasting, if you want something to heat up fast, you make a large delta. You want the turkey to cook faster, it goes in a hotter oven. You want to the car to go faster in a short amount of time, you give it more gas. See, you know all this. It’s a matter of applying it. So onto a roast as I see it.

It starts with charging temperature. I want the beans to increase in temperature at a pretty fast rate. To do that, I need a large delta. How large? That’s our first bump. For my drum roaster, I like about 60 F (and I mean 60F over room temperature – it’s the delta, remember?). For my standard oven, I like 100-120F. Why the difference? The semi-technical answer is convection. Basically, the more you stir something, the faster it can transfer heat. My roaster moves air. Most ovens do not. How did I find those numbers? By experimenting and roasting for the last 15 years. No, it won’t take you 15 years to learn how to roast. It took me that long to figure out how to describe what I was doing intuitively. I was roasting well in a few months. Moving on. So, I want a delta of 60. That means, if my beans are 70 F, and after everything ‘settles in’ after I put my beans in, I want the air temperature to be about (70+60) 130 F. And so I pre-heat to a level in my roaster that EXPERIENCE has taught me will give me 130 F. That means missing the mark sometimes. For MY ROASTER in MY SHOP, if I am roasting 5 lbs of beans, I need an initial temperature, on average, of 350 F. If I’m roasting 4 lbs, I might only go to 300F. And if I stuff 6 lbs in, I better take it on up to 375 F. In all those cases I should see 130 F after a minute or two for my air temperature and my bean temperature will be 75 F or so. Now, notice I said ‘on average’. That’s my loop hole. What if it is 50 F in the shop. That is another delta. Between my roaster and the outside environment and because there is a larger delta than ‘normal’, I am going to lose heat faster from my roaster, so I need to compensate by increasing my inside roaster delta a little by preheating a little higher. Maybe 375F (as opposed to 350) for 5 lbs. Or if it’s really hot in the shop, say 95 F, I can go cooler and only pre-heat to 300.

Yeah, it’s a lot of numbers. But are NOT supposed to memorize them. What I am trying to get you to do is ROAST. Roast. Keep notes . Learn YOUR roaster in YOUR home. And adjust accordingly depending on what your conditions are and what you want your roast to do.

Which is exactly what I do next. Control the roast. It’s kind of arbitrary, but I define ‘roasting’ as the continuous increase of temperature of what you are applying heat to. That means I always want the air temperature (ET) to be greater than the beans (BT). If it’s not, then there is zero delta, and if that is the case, there can be no temperature increase and that isn’t roasting. It’s stewing or braising or something other than roasting. How fast you want your beans to heat up is at the end of the day up to your tastes, but I like the whole roast to take between 14-20 minutes. What that means is I need to keep a large enough delta to keep those beans heating up so that I hit that time window. Again, experience has shown me that a delta 60 works well for me as my standard conditions. Up to a point. What happens at around 212 F? Water boils, right? Well, cocoa beans contain water and water takes a lot of energy to heat up and even more to drive off. What that means is that once my beans get to 215 F they have driven a lot of water off. Suddenly I need less energy or less delta, to keep the beans heating. It’s like carrying a back pack and putting out a certain amount of effort to go a certain speed. If you put the pack down, you need to expend less effort to go the same speed. If you keep putting in the same effort, you will go faster…and you don’t want that in a roast as that is a good way to get those burned notes. So that means decreasing your delta. In my drum roaster, that means decreasing the amount of fuel I am feeding and letting the temperature gap close. In an oven, that means turning down the thermostat 25-50 F (just like you have seen me recommend). At this point I like a delta 40 and I tend to keep it there for the next 1/3 of the roast or so. During that time, water keeps leaving. This is because we have been following the surface temperature of the bean. The interior is cooler and so contains water still. As that water leaves, you guessed it, we have to decrease that delta again or the roast will progress too fast. And really, it just keeps on like that until I’m down to a 10-20 F delta and my bean temperature is 250-290. Painting with a broad brush, Criollo tends to like a cooler final temperature than Forastero, but you have to determine that for yourself. Personally, I tend to roast all beans at least until I hear a few pops, and then 10-20 F more. Also, I tell A LOT by smell. Acrid almost always says your delta is too large. It can also indicate you are at the end of your roast or you are in the 260-290 range. I often end a roast if all the conditions are right. i.e. time is 14-20 minutes, temperature is 260-290, it is not acrid, pops have occurred (which don’t always) and the smell changes and softens.

So, what you might notice here is I too keep my air temperature below 300 in basically all cases. Even if I am roasting a robust bean that likes a high final temperature of 290, my delta is going to 10 or so. But even with that, I have a smaller sample roaster that I need to keep the delta larger because it is losing heat to the environment. For that one, my air temperature is often 320 F with a bean temperature of 285. There are just very few hard and fast rules. It’s all about technique and learning your roasting set up.

To really drive that point home, it’s like a new driver asking ‘ how hard to I have to push the brake to stop at that stop sign up there?’. How do you answer that? Hard enough to drop your speed so that you never skid, but don’t over shoot either. And you will have to apply less brake as you get closer’. Sound at all similar? It’s exactly the same. And the answers all change if you have a heavy or light load, if it’s raining or icy and how fast you are going when you start. If you are reading this, I suspect you drive. Think of it exactly the same way. It’s just a matter of learning to drive your roaster. Nothing more, nothing less. And you are only going to learn by doing, messing up, and learning from those mistakes. I can only give you suggestions and what worked for me.

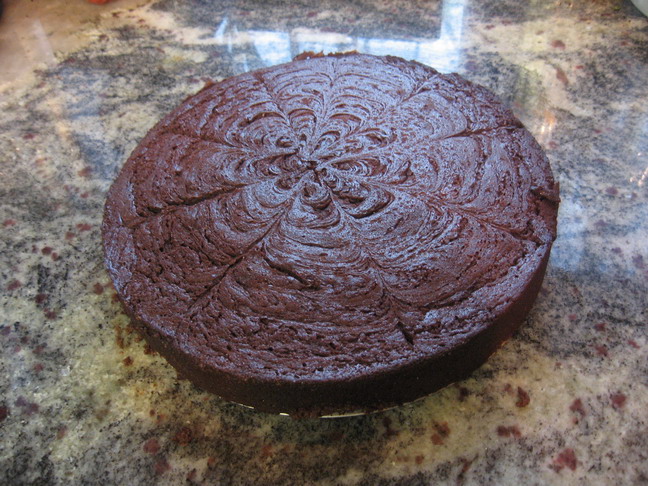

This time the roasted is on the right. And for those that want to know, this was done on P1, 1 lb setting, 16:15 minutes on the Behmor. 2.25 lb roast size.

This time the roasted is on the right. And for those that want to know, this was done on P1, 1 lb setting, 16:15 minutes on the Behmor. 2.25 lb roast size.