First time maker. We had some issues for sure but the one thing you for sure take for granted is how to work somewhat cleanly, and how to handle liquid chocolate well. We made a serious mess and it was quite a process to get the melanger clean again. So turn that big brain on and dump all your knowledge about working with chocolate and cleaning. Please be gentle with me.

Viewing entries in

Refining and Conching

I would appreciate if you could provide any specific bean recommendation to make milk chocolate.

Recently, I've been making honey chocolates (1 c cocoa powder, 1 c coconut oil, and 1/3 c honey) to remarkable success. However, my main issue is that the chocolate get soft (Though not melted) at room temperature, and it can get quite messy when someone picks it up to eat if it's not straight out of the freezer.

My question is what is the smallest serving size chocolate you can make in a melanger?

Today I am combining a few recent email exchanges. I hope you find it helpful.

Level: Novice

Reading Time: 12 minutes

I just read Dandelion’s new book and chocolate making seems very expensive. Isn’t there some other way make chocolate without a melanger. Wouldn’t a high powered vitamix work? How about the Champion juicer? Can’t I just run the sugar through there? It all seems so complicated. There should be a simpler way. I can roast coffee in a $10 popcorn air popper. Can I crack the beans In a corona mill and won’t that make chocolate?

Some of you long time readers might be a little confused with why I would answer these series of question when it seems really old news. The alternative was “What happens if you dip a cat in chocolate?” and well……

I have seen a large resurgence in these kinds of questions in the last couple months. New chocolate makers are coming in droves (of which I am thrilled by) and with it people seem to be trying to reinvent the proverbial wheel.

I in no way want to stifle questions, inquisitiveness and innovation but I also really want people to do a little research and maybe realize that nearly all of these questions have been asked before and answered (mostly with a 'no').

I want people to make chocolate. Keep that in mind. So ask yourself this. If there was a cheaper, simpler way to make chocolate, don’t you think I would be the first to announce it to the world? Really, I’m not ‘Da Man’ trying to keep secrets hidden. I've built Chocolate Alchemy on the philosophy that there are no secrets and I want to spread all I know.

I guess this is going to turn into a little review of bean to bar history interspersed with some of the questions. Let’s take it from the top down, going through each step of the process.

“You are selling beans from 2015. Aren’t they too old by now?”

I only sell beans that I’ve personally tested and verified. I make chocolate regularly and pull beans from our stocks once their flavor profile degrades. In some cases that is 1 year but many (most really) times it can be 2-3 years.

“Isn’t Criollo the best?”

They are just the rarest and generally the most mild. I hold by the stance there is no 'best', just your own personal favorite.

“Can I use an air popper like coffee to roast nibs?”

See the above discussion. I tried it and for a multitude of reasons it didn’t work. Mostly it has to do with scale and control.

“Won’t a coffee roaster burn my cocoa?”

No, you can turn it down.

“Will my chocolate taste like coffee if I use my coffee roaster?”

No, I have done it for years. Any coffee oils that might cross contaminate the cocoa would be absorbed by the husk which you winnow away. I’ve never even see that happen and I’ve used the same roaster for years.

“Can I use a home brewing mill to crack my cocoa?”

No, the gap (even adjustable ones) is too small.

“Have you heard of the Crankandstein cocoa mill? Why don’t you offer it?”

You could say I’ve heard of it. I invented it and had it built by Crankandstein. I no longer offer it as I find the Champion juicer does a better job for a similar price. Plus the Champion is multi-purpose. You can also make liquor with it.

“Doesn’t the Champion get to hot and destroy all the flavor of the chocolate? It seems like it would burn it”.

I discovered using the Champion Juicer for chocolate way back in 2004 and built Chocolate Alchemy and got this whole bean to bar movement going with it. If it had burned the chocolate or made it inferior I simply can’t imagine we would be where we are today. Yes, the chocolate gets warm, and even hot, but stays WAY cooler than when you roast. No, it does not harm the chocolate.

“Can I use the Champion 4000?”

I’ve not personally used one, but hear it works ok, but not as good as the 2000 I offer. And while I am talking about the Champion, there is a Commercial version but I have not found any difference in performance or longevity compared to the Household model, so I offer the less expensive household model.

“Do I have to use a melanger? It is so expensive. Can I use……”

I cut that off because of all the variations. You can insert Vitamix, blender, grain mill, and any other of standard household appliance and I will answer that I tried out every one of them over the years and would have told you if they worked. As it is, I specifically outline a bunch HERE that do not work. Again, I WANT you to make chocolate. If I could lower the financial bar, what possible reason would I have for not doing that? The answer is none.

I’m going to take this opportunity and say I appreciate that this is not an inexpensive hobby. But when I started down this chocolate making at home road in 2004, before there was a bean to bar movement, it was not even possible to make chocolate at home. Aside from no knowledge base, all the equipment was industrial. There were no melangers. The cheapest winnower was $2000 and did a huge 2 oz a minute. There were no roasters. A basic set up would have cost you $100,000 or more. Now a good setup is $1000. That is two orders of magnitude. Please keep that in mind is all I’m saying.

“I’ve read that melangers make inferior chocolate and that you need a mill and conche to make good chocolate.”

The WHOLE bean to bar movement was built on the stunning results of stone melangers. I think that evidence right there speaks for itself as an answer to that question.

“Why don’t you invent a small $100 melanger? I’m sure you would get a lot more people into chocolate making.”

I bet Apple would sell a lot more Iphone X if they were $50 too. I would have done it if I thought it was possible but there is a lower limit to material and building costs. And really it comes down to scale in this case. Although there are 1000s of melangers out there, I would bet there are millions of iphone Xs already out there. If I made 100,000 small melangers I could probably do it for under $100 each but there is that small issue of the $10,000,000 needed to do that. As big as the bean to bar movement gets, I don’t see it ever being worthwhile to make 100,000 melangers at one go.

“I’ve heard you can’t use a tempering machine with bean to bar chocolate, that it is too thick. How do you temper?”

I am baffled where that opinion came from. You can. Certain extra light roasts that retain moisture might be a bit thicker, and some makers don’t like using cocoa butter (which makes for a more fluid chocolate), which I don’t understand, but you absolutely can use a tempering machine. That said, they are expensive and I don’t see a reason not to hand temper or to use Silk which is nearly fool proof.

That is a selection of questions that have come in the last couple months. I said at the beginning I wanted to give you a basic history of bean to bar. Dandelion’s book showed the successes very well, but what they didn’t describe (nor was it their place to) was the multitude of failures I went through. It would be impossible for me to tell you everything I tried but know that if it was a common household item, I tried it and if you don’t see it as an option, it is because it failed. And when I say failed I mean were too expensive, too DIY, too cumbersome, too hard to work with or literally just failed.

What are some of those things that didn’t work ?

- Ice cream maker (conche)

- Rock tumbler (refiner/conche)

- Air popper (roasting)

- Ball bearings in mixer (ball mill refiner – expensive)

- Rolling pin (cracker)

- Mortar and pestle (well, becaue)

- Hand peeling (too hard)

- Corona type mill (poor results)

- Champion Juicer (refining sugar – fail)

- Champion Juicer (winnowing - hard on machine and tasted bad)

- Vita-Mix (burned the chocolate)

- Other Juicers (ride up and fail)

- Home convection ovens (under powered)

- Meat Grinders (crackers and refiner)

- Food processors (refiner)

- Grain mills (cracker and refiner)

- Coffee grinders (refiner)

- Indian Wet Grinder (burned out, but we modified them to the Melanger you now know)

And that is just a sampling. Various other Rube Goldberg type contraptions were tried and there were many variations of those above. All that and more brought us to this place at this time where the web is full of free information on how you can get into chocolate making for the barest fraction of what it would have cost 20 years ago.

By all means keep trying though….but maybe not the same things others have tried and proved doesn’t work. There is that semi-urban myth that the definition of crazy is doing the same thing over and over expecting a different result. Try not to be crazy.

Just like they say there are no new ideas for story lines anymore, I am pretty confident there are no longer any obvious solutions for making chocolate simpler and significantly less expensive than there currently is.

Regardless, keep experimenting, making and asking questions.

Cheers.

I've been reluctant to grind for a long time because I thought most volatiles were driven off in first 12 hrs and

I was wondering about adding flavors to the white chocolate in the melanger? At which point? I was considering using oils unless you have another recommendation. Do you know ratios to attempt to begin with? Thinking of Orange, Lemon, lavender - not altogether.

I have read about that volatile compounds are released and the acidity in the chocolate drops as it is refined. I tried to test the changes in pH. After 12 hours there was hardly any change in pH (7.1 to 6.9). It clearly tastes different even after 12 hours but the acidity didn’t change. How can I measure and track and acidity?

I notice you advocate dropping your beans into a hot roaster. I assume this is because you want Maillard reactions and Strecker degradation products. Is there a certain temperature that works best for these products?

I have learned that some makers (myself included) are lightly baking (in the oven at ~170F) their sugar on a baking sheet before it goes into the melanger. The idea being that the higher temperature of the sugar will maintain the liquor at a higher temperature allowing you to feed the sugar into the melanger more quickly. I have however

Level: Novice

Read time: 3 minutes

I am confused about the issue of “burning” or “scorching” chocolate. It is widely advised that when melting chocolate for tempering, one should not let it get above 120º F or else the chocolate will be irreparably damaged and will not be able to be tempered. However, while grinding in the melanger the chocolate gets up to 140º F to 160º F (the hotter being advised as a conching temperature). How come it is not damaged at this point but it will be if reheated/remelted later? I see some people talk about tempering straight from the melanger – which means essentially cooling from >140º F straight down to 84º F or so. Is there something about the chocolate cooling and “curing” after grinding, after which point it should not be brought above 120º but if tempered from these higher temperatures right away (without cooling first) it is OK? Any insight into this discrepancy would be appreciated. Thanks.

Nice observations. When faced with contradictory facts, the key is to tease apart which fact actually isn’t one.

In short this is a false fact from the days before home chocolate melting when people really didn’t know or believe they should gently heat chocolate. And what exactly it meant to heat chocolate gently. It seems like many people would put the chocolate in a pan, put the pan on the stove (on low of course) and proceed to burn the chocolate. How?

The issue wasn’t so much that the chocolate got to 120 F or 140 F or even 180 F, it was that the surface of the pan got much hotter. As in 400-500 F. And that is more than hot enough to burn chocolate. Now, if you constantly stirred, and mixed and kept that heat distributed, there wouldn’t be an issue. But people don’t tend to do that. They let it set….and burn that layer of chocolate that is setting on the bottom of the pan.

This is why it is pretty universally suggested that you melt chocolate in a double boiler. There is nothing magical here. It’s just that 212 F, the boiling point of water, is below the temperature at which chocolate will burn.

So feel free to heat your chocolate up. You can go beyond 120 F….if you do with properly. In a water bath. A warm oven does well too since the warm air has so little heat capacity. I often set my oven to 150-170 F and put much chocolate in there. It never burns and I don’t have to fret over water being near my chocolate.

That said, a variation of this is that you MUST heat your chocolate up to 120 F when tempering. This too is also untrue. It won’t hurt anything but it isn’t necessary. The though is that you have to take it that hot to destroy all the crystals in the chocolate do you get a good temper. As anyone who has messed up tempering by going to the mid 90’s know, all your crystals are fully melted at 100 F. Anything above that is just wasting time and energy.

Level: Alchemist

Read time: 6 minutes

I really want to make chocolate with honey. I’ve seen it out there so it must be possible. How can I do it?

Not really. Every chocolate with honey out there I have found has turned out to only seem like chocolate. What I mean by that is that upon talking to the makers, I’ve learned that none are really tempered and have a tendency to separate after a short amount of time. In addition, they stir the honey in at the very end, very, very gently. Too vigorous and it would seize.

That all said, it got me thinking. I went down the rabbit hole of research and came up with a couple ideas I thought might stand a chance. My goal here was a real tempered chocolate, using honey refined in the melanger.

The issue here is of course the water. My thought of course was to remove the water.

I came up with the brilliant idea of making a caramelized honey not unlike the caramelized sugar used to make praline. Boosted by someone else's success, I tried it myself.

Sadly, it didn’t work. You do end up with a hard honey candy, but it is so hygroscopic it was impossible to work with. By the time it was cool enough to work with, it was so tacky that it was unusable. Within a couple hours it was flexing and the next day it was trying to flow.

The next thing I tried was dehydrating the honey. Past experience told me I could not just dry it in the oven. It becomes a solid, sticky mass that holds too much moisture. Did I mention it was hygroscopic? So instead I coated my roasted nibs with the honey and put that into the oven for 12 hours. I weighted the entire mass before it went into the oven, noted the approximate percentage of water in honey (18%) and kept weighing the nib/honey mixture until I was below that amount and stable for a couple hours.

By the end the nibs were dry….but just slightly tacky. That didn’t bode well.

To try and help the process along I pre-ground the mixture. Something I never do, but every little bit of help seemed prudent here. My thought was if I could spread out the honey enough, then powder it, I could keep the moisture away from the honey.

I proceeded to put the mix, little by little into the melanger. It all went in, and started to fluidize and flow. I really thought I had it. Did you catch the past tense there? Yeah. It failed. I came back about 12 hours later to a complete mess. It was still running, but it looked really strange. I can’t even begin to describe it. It was kind of coarse, but still flowing. And chunky. But not really sweet either.

Upon turning it off and inspecting it I found this thick, gooey, kind of nasty ring of what I guess was wax around the center shaft. Apparently there is quite a bit more to honey than just sugar. Wax. Propolis. Higher sugars. Basically a whole bunch of stuff that didn’t play well at all with the cocoa butter.

At that point I stopped. This was not the way to go.

So, I don’t have any good answers for you. You can try stirring it in at the end, and attempt to temper, but frankly I would not hold my breath on this.

Regardless, learn from my failures. You can't win them all and failure is always an option.

If anyone has any other ideas, I am more than happy to try.

Now that you have a cocoa butter press, have you experimented with different ways of making chocolate (to improve flavor/texture/etc...)? While I realize that "just because you can, doesn't mean you should".... My mind is now spinning with thoughts of things that could be done during the process... pressing butter out of the liqueur before putting it into a melanger to refine/conche... Doing something to warm/process the butter to change its flavor before reintroducing it to the cocoa "powder"... different ways to introduce the sugar into the butter and/or powder?

Well, the first answer is that no, I have not yet experimented with this. I am actually in the middle of a long series of oven roasting tests. So far I have 10 different combinations of roasting beans and nibs in a conventional oven. More on that later.

For those that are missed the 'press' that is being discussed, it is the Nutrichef oil expeller that works on cocoa beans and gives your own cocoa butter.

What can be done? Well, given we are limited to a Melanger, I think some of our options are limited by the necessity to have a flowing product. You could press some cocoa butter out, but you still need to maintain 30-35% fat, so even with a 70% dark chocolate, you are already there and can't remove any cocoa butter.

I am glad you mention 'just because you can, doesn't mean should". We CAN process our chocolate more, but I'm not sure we should. It's one of the big reasons I constantly make it known that I don't find you can make a good chocolate from cocoa powder. It was been processed too hard. But there is also no reason not to try. This is fresh cocoa butter and powder and is 'processed' more gently than others by nature of the small scale. I will certainly try making a batch recombined. For science's sake.

What does come to mind though is a cocoa powder, cream powder chocolate. At 72% fat in the cream powder, you have the ability to get that chocolate flowing again. That is now on the list too.

That all said, I think the first place to start is making your own butter, and using it in 5-10% amounts in your existing recipes and seeing if it makes a difference. I know it can make a radical difference in a milk chocolate where there is 30%. Time to play people!

Finally, I will mention that the resulting cocoa powder is not as fine as commercial powder. But it is pretty fine (straight out it is coarse, but a quick run in a whirly blade grinder gets it fine). And I've been using it in mochas (it mixes nicely with hot water), hot chocolate (ditto with hot water and sugar) and quick mole spicing (I sprinkle it on sauteing chicken and add a little chili sauce).

So, what do you folks want me to test?

Here is my experience with Nicaragua.

• Last summer. Roasted at P3, 18 minutes, may or may not have been before the afterburner crapped out but it should not have made this much difference. It was exactly as you described it and I loved it: As a chocolate, the nuttiness stays on, along with the richness of medjool dates, molasses and interesting tobacco (leaf not smoke) notes. A good full, balanced chocolate flavor wends it's way all through the taste and aroma, with not one aspect dominating the profile.

• Recently, P2, 16 minutes: Fruit bomb. Like the older Peru beans or even Madagascar

• Recently, P4, 20 minutes. Just slightly less of a fruit bomb. No nuttiness and not a hint of the tastes you describe.

• Recently, P2 for 23.5 minutes. A burnt fruit bomb

I don’t think any permutation of roasting is going to give me the flavor you describe, and I had before. The next time you are testing a roaster or grinder, will you humor me and make some of this and see what you think? I swear to you it is a different bean. Do you mind if I send you samples to taste? I have a bar left from last summer and some of the more recent ones so you can taste for yourself.

This week isn’t quite so much a question as a story. A mystery as it were. Who killed who where and with what. The above was part of a dialogue trying to work out what was going on with a recent change in flavor of a chocolate. It was a matter of deduction and clues and a bit of sleuthing.

As you can see the bean in question was from Nicaragua. From the time of the good chocolate and the bad chocolate I had received in multiple shipments. But the container lots were identical. In theory the beans were the same beans.

I both tasted some of the bars in question, and it was amazing just how radically different they were. I suggested different roasts to no avail. We made a little headway determining the afterburner in the Behmor had burned out, so the roasts were not identical But after fixing it, it still was not right.

I made chocolate here from the new (bad?) beans….and it was like the good chocolate. It was a real head scratcher.

I had basically proved the beans were the same by being able to replicate the chocolate here. And chocolate may have lots of variables, but it doesn’t change in flavor just randomly. The key was finding out what was different. Recipe? Sugar? Cocoa butter? Check, check, check.

I really wish I had the ability to write this up as a big, draw you in mystery scenario…but alas, I am not that good. Suffice it to say we found out the issue. Winter!

The new chocolate had been made during the winter….and the key was noting that it was changing as the seasons go cooler. The melanger had been being run in an unheated room on the floor. The refining chocolate was much cooler during the winter than when it was made in the summer. The key was noticing that my setup here was not affected by the climate (they were in the bitter wasteland of rural Vermont). Basically, different temperatures caused different chemistries. Some of the more aromatic fruity compounds were not driven off. Likewise the nuttiness was not able to develop.

The solution was to put the Melanger into an unsealed cardboard box. The motor generates quite a bit of heat and was able to create an environment that mimicked summer conditions. A new batch was roasted up with the old profiles. Refined in a box….and just like magic, the bad chocolate was good again.

So, there you go. We are coming into the winter months. If you have been refining ‘au natural’ and want your chocolate to stay the same, maybe look at a little supplemental heat. The melanger in a box (make sure it’s not sealed up, it can get too hot) can create just the right environment.

Send in your Ask the Alchemist questions to questions@chocolatealchemy.com

Can am using a micrometer to measure the particle size of my chocolate but it doesn’t work. I get different results every time. Sometimes they are very large (over 100 microns) and sometimes very small (less than 5 microns). It doesn’t make any sense as the chocolate seems smooth to me. HELP!!

It's important to have the right tool for the right job. Every tool has its limitations, and once you determine the correct tool, it is just as important to understand how to use that tool. For most of the people reading this, a micrometer can be the right tool - as long as use it correctly. Actually, the mouth itself is probably the right tool. Given sufficient experience and feedback via a tool, I've found that some people can 'resolve' down to 10-15 um particle size (the largest particle), within +/-5 um. As I’ve said before, most people making chocolate are not going to need an understanding of particle size, shape, or distribution, and spending lots and lots of money to get a number that your tongue could probably tell you.

It is also very important to ask yourself "why do i need this piece of data, and what will I do with it". If the number itself isn't important to you , and really if the information you're looking for is 'Does my chocolate have a good mouthfeel or not?' then just put it in your mouth. If you want the number to gauge progression quickly, and to calibrate your mouth, then a micrometer could very well be the right tool for you.

I actually had to dig a little deeper with this person to find out what micrometer they were using and what their technique was. As it turned out, both were causing the issue of not having good reproducibility and values that were not right (both precision and accuracy were off). Over the past weekend at the NW Chocolate Festival I had the opportunity to speak with someone who has been in the chocolate industry for over a third of a century and whom I respect greatly. We talked a bit about micrometers, measuring technique and when it is and isn’t useful. Much of this comes from him, interspersed with my own knowledge of analytical techniques.

It is critical to have the right tool for the job. In this case, micrometers come in two types that deal with how they close and stop. One is a ratchet and the other is a slip clutch. You want the later. Very simply the ratchet can crush your sample giving you a false low reading. You do not want this style

http://www.google.com/shopping/product/11394996720134678078?hl=en

The specific one that was suggested was this one:

http://www.longislandindicator.com/p109.html

Yep, dials. Analog. You have to learn how to read it. Can you use digital one? I’ve given you his and my recommendation and you can use what you want. But remember, you get what you pay for and GIGO. If your cheaper digital one isn’t accurate, can’t be calibrated or isn’t reproducible, you have basic just flushed your money away.

You now have the proper slip clutch micrometer. How do you use it? Well, first and foremost, NOT like this.

If you do the larger particles are going to follow gravity’s lead, and flow to the bottom, and then out as you close the barrel. The result will be artificially low biased numbers. You need to turn it 90 degrees like this:

Pic You place the drop of chocolate on the barrel and rotate it up until you feel the clutch slip. Record your number, clean it and test it again. I would personally recommend at least 3 times while you are learning and until your results are all within 10 % of the average. And even then, duplicates never hurt.

So, I skipped past the ‘sample’ preparation. Chocolate is thick. There are a lot of particles there and the more there are, the more the more they can resist crushing together. In a perfect world, you would want a single layer of particles. In reality, that isn’t needed and is actually really hard to get. A good compromise is to dilute your chocolate sample with somewhere between 2-5 parts cocoa butter. Frankly, experiment and see what works for you. Your goal is reproducibility.

Back to sample preparation. Take out one teaspoon full and mix it with one tablespoon of cocoa butter (1:3 dilution) and mix it very well with a spatula on a plate for a full minute. Make it look even.

Then put a drop on the barrel and there you are. Keep the barrel vertical, close it up. As you do, what particles are there are going to compress. Some will crush. They will compact against others and crush a little more. At some point the pressure of the slip clutch will push back enough and that will be that. You can take your reading.

What does that reading REALLY mean? It’s a number. It technically isn’t the largest particle because some have been crushed so it could be low. And some stack together so it could be high. And it says virtually nothing about the smaller particles and distribution is also not there. But it does give you a numerical ball part of your largest particle sizes. This has been shown to have a pretty good correlation to the maxima on a distribution plot. In this case, 10-15 microns seems to indicate good, smooth, very fine chocolate. But keep in mind that number is specific to this testing method and the dilution you pick. So keep your dilution and technique constant and for in house use for the most benefit of this number. And use it to try to correlate what you are feeling in your mouth to what your numbers say.

Do you need a micrometer? I personally don’t think so as I think your mouth is just fine. But that said, I’m a number’s geek and tracking progress objectively is almost never bad. You have to be the judge if it is right for you.

Send in your Ask the Alchemist questions to questions@chocolatealchemy.com

When is the best time to add the sugar and cocoa butter in the grinding process?

There isn’t one.

That said, you have some choices and those choices have the potential to change how your chocolate behaves and tastes.

I personally like to add the ingredients in the order that makes my life easier and does not over stress the machines. That means melting my cocoa butter, and lecithin if I am using it, and adding it to my warmed melanger bowl (the stones are warm too). This gives you what is called a working fluid. The melangers were after all initially WET grinders. Dry material has the tendency to pack down. After that I either add my melted cocoa mass or handfuls of the warmed cocoa nibs. Every 15 minutes or so I add another handful nibs. In that time the previous addition as started flowing. Once I have a pound or two in there I usually alternate between sugar and nibs, under the premise that sugar is hard and makes a good abrasive, even if it is getting ground down at the same time. Basically it helps speed/shorten the time between additions and lets me be done sooner.

But you have lots of options. You can add the sugar as I’ve done above. Or you can wait until all the nibs are flowing. Or you can let your chocolate mass refine a few hours to a day before adding the sugar. Depending when you add it, there is the potential for the chocolate to taste different. At the beginning there are more acids and water present. Under some circumstances (yes, I am being purposefully vague because the sugar chemistry is a bit much to get into here) this can lead to chemical reactions which may or may not be to your liking. Adding the sugar just an hour later is a good halfway point, and a day later eliminates most of these type reactions. Do you want these reactions? Well, maybe. It is very subjective and to one’s own tastes. Basically you have to try it and see. I’ll say my tastes tend to liking many complex reactions so it is fortunate that I add my sugar sooner. I have also tasted chocolate made from sugar added a day later and it was a thoroughly enjoyable chocolate….just different than my own.

The same goes for cocoa butter. When it is added at the beginning, your resulting chocolate is going to be less viscous. More fluid. That means two things chemistry wise and one from a physical standpoint. When thicker, reactions are going to be a little slower, but it also means volatiles won’t be volatilized as quickly. With a thicker mass, your melanger won’t refine quite as fast as directly compared to a thinner mass. This means a longer run time but also more time for reactions to occur. It is the same as before. I like running the melanger with a thinner mix where reactions happen faster and everything is ‘set’ early. But I have again tasted batches where the chocolate was run thick, but longer, and the cocoa butter was added right at the end as a viscosity modifier. It too was great, but different chocolate, than mine.

And don’t forget, all beans are not created equal. What works (for your tastes) for one, may not yield the most favorable results for another. And sadly I can’t help or predict that in the least. All I can tell you is you have to experiment and that in some (but not all) cases additions of sugar and cocoa butter at different stages can result in pretty different results.

Send in your Ask the Alchemist questions to questions@chocolatealchemy.com

I wanted to ask your advice on a spectrometer. I know that we should get our chocolate mass to a certain micron range. Would this be a good one to get or have you used a different one given the price? Also, do you recommend any other helpful tools to help with quality assurance?

http://www.amazon.com/dp/B00S941UQM/ref=wl_it_dp_o_pC_nS_ttl?_encoding=UTF8&colid=3C39Q9TYAUQ03&coliid=I5H0ZZ8Z4OP88&psc=1

My advice is don’t get hung up on numbers. At least in this and a few other cases. I like ‘numbers’ when they actively help me either repeat a process or verify a process is where I want it. But numbers for the sake of numbers is just wasting time. This isn’t quite that later case, but it also isn’t helpful.

I’m going to pick on your premise. You do not actually know your mass needs to be in a certain micron range. You know that your chocolate needs to be smooth. And smooth is a tactile sense, not a number. If you want to know if your chocolate is smooth enough just taste it. I’m dead serious about this.

There are a few reasons. But the one I just made is the main reason. You want to know if it’s smooth so use your ‘smooth’ detector. Your tongue! It is the best tool for the job.

You mention a spectrometer. First off, your link isn’t for a spectrometer. It is for something called a Grindometer. I would specifically not use it. It doesn’t really give you that much data. To paraphrase a couple sources, Grindometers are built to give a very quick indication of the high end of the particle size distribution, allowing production processes to be followed in real time. Again, your own perception will do this.

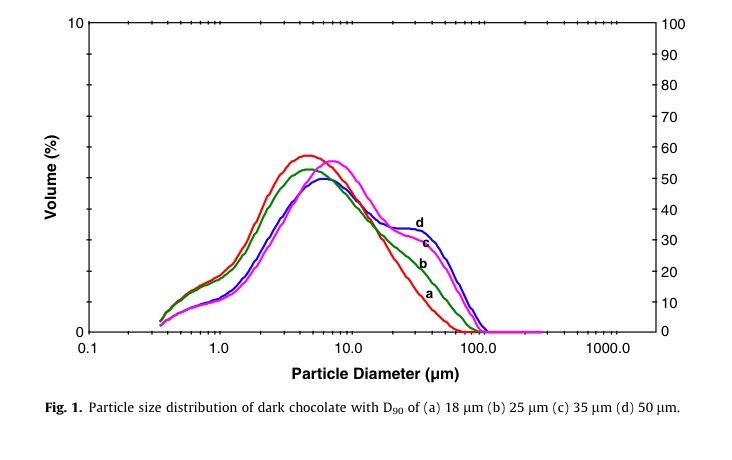

Here is the problem. The Grindometer tells you top end. But our mouth doesn’t work that way. Our perception is complicated. We take an average, with a sensitivity to the larger particle sizes to determine whether something is ‘smooth’. Basically we interpret qualitatively (i.e. without numbers) the particle size distribution in what we are tasting. Even just a few particle that are larger than the average make us say ‘coarse’. Under some average threshold we say ‘fine’. But your Grindometer is only giving a number that basically says “most everything is under 110 microns’. Not real helpful. Why? Have a look the following. It’s a particle size distribution plot of four different chocolates.

They spread the gamut of very fine to acceptably smooth. The Grindometer would tell you these all had particles in the 80-100 um range. Way coarser than the traditional bench mark of “less than 35 microns”. One reason it is not very useful. But I can hear you now. ‘I can use 80 as too fine, 85-90 as perfect and 100 as coarse’. Not really. You would be really hard pressed to see that on the Grindometer. It’s the difference in theory and practice. But for the sake of argument, let’s say you disperse your chocolate in some oil so it’s easier to see and you can see the difference. It is fully possible to have a chocolate where the largest particle is 80 um and the chocolate per your mouth is very coarse. How and why? Because of the averaging we do. Note the labels on those 4 plots above. 18 um, 25 um, 35 um, 50 um. Those are the weighted averages of the entire distribution. When you hear that chocolate should be 35 um, THIS is what they are talking about. Not less than 50 um, or less than 35 um. Not exactly 35 um. What that means is you can have a plot like the one below. There is nothing larger than 80 um, but the weighted average is 65 um so it’s going to seem coarse yet your Grindometer would have you believe it is super fine and ready to go.

Basically it’s the wrong tool for the job. The same goes for people using micrometers. I have heard it a lot, that they use them to verify they are at 50 um or 35 um or whatever….except assuming it even works (which I am skeptical about as they aren’t comparing it against a known value), it still is only giving you the largest particles which are basically unrelated to mouth feel in the critical range.

Could you use a particle size analyzer such as was used to make those plots? Sure. Maybe. The main question I would put to you is WHY? What are you going to actually do with the data that is worth $10-20,000? Especially when at the end of the day it’s the mouth feel you are concerned about and the best test for that, as I’ve said, is just to taste it and determine the mouth feel for yourself.

To close this out, I don’t want to leave you with the impression I am against fancy tools and numbers. Heck, I was a chemist for many years and love that stuff. But that experience has also shown me that trying to correlate complex numbers and graphs to the human perceptions might be sexy as all get out in a research setting, it has a tendency to fall apart in the trenches of daily production. At the end of the day your senses are amazing. Use them!

Send in your Ask the Alchemist questions to questions@chocolatealchemy.com

I was wondering if you could explain or give your opinion about two steps of the process.

1. Roast 2. Crack with champion juicer 3. Winnow. 4. Pre-melange using the champion juicer to turn the beans unto a paste/liquid 5. Melange with spectra 11 for varying amounts of time.

My questions have to do with the fourth and fifth step.

First, what are the advantages of using the juicer initially to turn the beans into a liquid? This step seems to be the slowest and hardest (from a technical perspective) because the bean and machine take a long time to get hot enough to clear the juicing screen--this includes the use of a blow dryer to heat things up further. Other chocolate makers also seem to use this step (e.g. Dandelion) but I don't understand how this helps flavour or texture advantage compared to putting the windowed bean straight (and slowly) into the spectra.

Second, I think I understand that the heat created by the melanger is responsible for eradicating some of the off flavors. It also seems to be the case that the same heat works to mellow the good unique flavors of the bean or at the worst eradicate the uniqueness. With long conching times I'm worried that I won't be able to keep all that great flavor. Have you found this to be true? And if so have you tried, with any success, controlling the temperature of the melanger by releasing some of the tension keeping the the rollers down to reduce frictional heat? Can you blast the melanger with heat for the first few hours to remove the bad flavors?

A little history. There use of the Champion juicer came about incrementally. It was the first house hold appliance I found (yes, I’m the one who ‘discovered’ it could be used for chocolate some 12 years ago) that could take roasted cocoa nibs to unrefined cocoa liquor/mass. It was not until a year later or so that I worked out that a modified Santha Wet grinder could be used to refine and conche (i.e. mélange) chocolate and worked with Santha to product the first Santha 10 Melanger (which has progressed to the Spectra 11).

At the time one of my guiding principals was approachability. I wanted it to be relatively easy for people follow the process and the Champion helped in that regard. The other option was to grind the nibs directly in the Santha 10. But unfortunately it was not up to the task initially and it could take a hour or more to get just a couple pounds incorporated and I found that was a great turn off for many people.

So that is/was the basic advantage of the Champion step. Take ½ hour and make 4-5 lbs of liquor that could easily be added to the Melanger. It is also worth mentioning husk. The Champion as you know has a screen at the bottom that the liquor comes out of. It also filters out any husk that was left in the nibs. Before the invention of the Aether and Sylph home winnowing was much harder and less efficient. With the advent of those winnowers that need has decreased.

So to answer your specific question, you don’t understand how it helps flavor or texture because you are looking for the Champion to affect flavor or texture when it does not. Its two jobs are to liquefy the nibs into liquor and remove any remaining husk. If you winnow well and don’t mind taking the time to add the nibs to the Melanger slowly, then there is little need for the Champion step.

One other side note here. You really should not need to heat anything up externally while using the Champion. It creates its own heat when used and if it is not, something isn’t quite right.

On to question two. Your language is kind of aggressive there. ‘Eradicating’? I guess that is somewhat accurate, but it is a bit overkill. It really more allows volatile compounds to escape the chocolate and oxidizes other compounds in the chocolate chemically change to ‘softer and gentler’ flavor components.

Let’s get something out of the way. Tension. It really is pretty much binary. Whether the screw is just barely engaged or screwed all the way down, the tension produced is virtually constant since you have to compress a heavy spring just to engage it and the distance traveled over the span of a few turns is so minimal. So, yes, I have tested the tension/friction/heat correlation and found it basically non-existent.

. Long conching times. Too much is made of this. ‘Don’t go to long – it will make bland chocolate.’ ‘You have to go 72 hours – it’s what the Swiss do.’ In theory it is possible but it is an extreme case I have found. You really need to start with a really mild bean, roast it particularly long, mélange it significantly hot and go a long time and you can end up with brown cocoa mass. It honestly it takes a LOT of work to do that. And it really comes down to the fact that THE MELANGER IS NOT A CONCH! Likewise, it is NOT A REFINER. It is a MELANGER. Did that get your attention? I’m serious here. What we use at home is a Melanger. It refines and conches at the same time and consequently it is pretty well inefficient (compared to ‘Refiners’ and ‘Conches’) at refining and conching. It’s why it takes 18+ hours at a minimum to refine to 20-30 micron as opposed to many function build refiners that take minutes.

The same with the conching aspect. That oft touted magic ’72 hours’ for quality chocolate is a result of some tossed out factoid that some European chocolates were conched (in a purpose built Conch) for 3 days.

Melangers are not that good (read efficient) and show self regulation and diminishing returns over time. What that means it is nearly impossible to over refine or over conche in one. Over the years I have tried. Currently my longest test was 10 days. The short result was that the chocolate was ‘ready’ after 30 hours. And slightly different at 72 hours. At 5 days it was more mellow but by no means boring or ruined and at 10 days, I could not tell it apart from the samples of days 6-9.

As for blasting it with heat. No, this really does not work to well. It might drive off the volatiles more quickly, but it is just as likely to drive off chemical pre-cursors of compounds you want in your chocolate that will develop into complex flavors later.

So mostly, RELAX about it and stop trying to micro adjust the process where the effects are just lost in the noise/randomness of the process.

I’ll relate the three times I made un-unique and down right boring chocolate.

1) I started with a delicate Criollo. I roasted it a touch heavy. It put it in the Melanger for 3 days at 130 F (still flavorful) and THEN added heat (to 155 F) and ran it for another 24 hours. This was then boring chocolate.

2) I used a blow dryer to heat the chocolate directly. It effectively stripped the chocolate of flavor. Not so much the heat but the actively blowing air.

3) I added 1 t of baking soda per lb of chocolate and ran it 2-3 hours. Boring!

In all three cases I pushed it to extremes ON PURPOSE. There have been many a batch of test chocolate that I’ve run for 4 days just because I busy and didn’t feel like dealing with it….and it was just fine and fully good enough for me to approve the sample for purchase. Yes, it was some different….but I’ve made two batches of chocolate in theory identically and had them come out different, so that does not say a whole lot.

I developed most of these procedures and equipment for approachability. What that means is you may not have the control you think you want, but it also means that if you give both a chance you will make good if not great chocolate time and again.