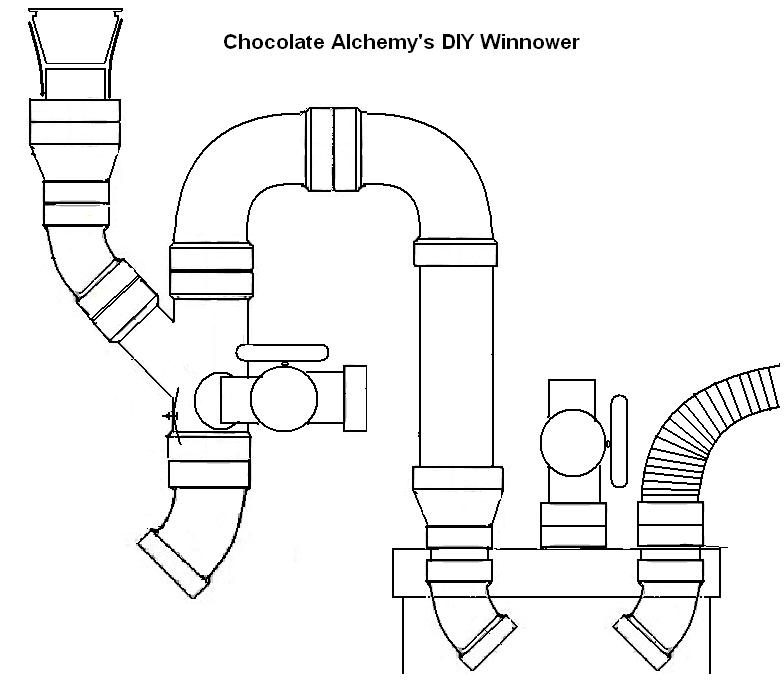

And here are the more detailed plans.

And here are the more detailed plans.

Feel free of course to e-mail me if you have questions. If you build it, you will have to 'tune it' by adjusting the two valves to regulate the air flows. Off hand, as an estimate, the valve on the left can be all the way open for raw nibs, and about 1/3 close for roasted nibs. The valve on the right is adjusted to regulate the total flow and is closed until husk stops falling out of the nib exit. Again, I'll detail tuning in greater depth, and email if you want more information now. Finally, and please pardon my soapbox (stepping up as we speak), but PLEASE don't ask me why I didn't design it this way or that way. I can't answer that negative question. The base answer is I've designed and built something that works with parts that are off the shelf, and/or very simple to make if you have a mind to. And I don't fix what isn't broken. Is it perfect? No. Is it $35,000? No. Is it $5,000? No. Am I a little defensive - yeah, maybe a little. In almost every case the answer as to why this or that isn't in there is cost and ease of making it. This is an elegant, simple design that works. Are there places for improvement? Yep, and they will most likely add cost because they will be more complex. (stepping down). But right now for about $50 in PVC, plus a Champion (which you may well have), and a Shop-Vac (again that you may have), plus a couple hours time, you can have an automated working winnower. That all said, feel free to ask why I designed it a certain way (do you note that difference?). I am more than happy to discuss why it is designed as it is and how it works.