Level: Apprentice

Reading Time: 10 minutes

I think I'm confused by something and I'm not sure what. On this link Behmor displays their roasting profiles as percentage of power over percentage of time. I recently purchased a roasting drum from RK Drums, and in their "mandatory reading" they talk about why it isn't necessary to know the exact temperature of the beans. They too express their targets in terms of temperature over time so certain phases of the roast happen within the specified time ranges.

I'll be using my drum over a gas grill rated at 48,000 BTU output across four burners. The only control I have over the system is the amount of gas sent to the burners (BTU output) and the bean load. As noted in the RK Drums page, it's not cost effective to have a temperature probe in the rotating drum, so the only input I can currently measure is the temperature inside the grill. If I understand this at all, I believe the Behmor profiles work because they know the power output of their roaster, and by allowing you to select the weight of the load, it can calculate the appropriate length of time for the roast segments. Can I not do the same thing with my grill - calculate the appropriate length of time for the roast segments based on the amount of beans I'm roasting and the rate of gas flow to the burners - without having to constantly monitor the surface temperature of the beans?

The main reason you are confused is that all beans are not alike. RK Drums is talking about coffee beans. I assume you are talking about cocoa beans.

Let’s start off with a quote from RKDrums

“While knowing bean temperature would certainly be ideal. “

Incomplete sentence aside, Shane (the owner of RK Drums) readily states having a bean temperature is ideal. But he is also correct. In coffee you don’t absolutely have to have an exact bean temperature the entire time and the reason isn’t because you know the BTU’s of your system. It is because you have two HUGE landmarks in coffee roasting called 1st and 2nd crack that occur within pretty tight temperature windows. In other words you do have some bean temperature data when roasting coffee.

With an input setting (your dial on your grill), an ambient grill temperature and a time at 1st crack you can plot a graph for an approximate roast profile and fine tune it from roast to roast.

In cocoa though there are no predictable cracks or any other kind of marker. You are driving blind.

Shane also says “Since, again, coffee roasting is a linear operation. “

This just isn’t true for coffee and likewise isn’t true for cocoa. We have talked about this a lot. It is really a falling curve.

That said, it makes a valid point. If you are expecting first crack at about 12 minutes and it arrives at 10 minutes you know you are running hot and should turn down your heat. Ditto if it arrives at 14 minutes, you know you are a little cool.

In either case you know your bean temperature is 400-410 F because that is roughly where first crack happens. THAT is the really important part. You have a landmark. You have a time and temperature. That allows predictions that are close enough to a linear equation. But in cocoa you are completely missing that landmark.

Without that landmark you don’t know when or if to turn your burners down. It’s a simple as that.

I know I am repeating myself but I want it very clear. In coffee you can cope without exact temperatures because you are given temperatures (400-410 F) at some point. You are never given that feedback with cocoa. Aroma (especially on a grill) just isn't enough.

So let’s talk about getting you that temperature data.

Shane says “It's, however, not cost effective related to its benefit “

I’ll respond to this by a quote from Abraham Lincoln

“Don’t believe everything you read on the internet”.

I hope that makes my point (including what you are reading – please verify what I say).

I’ve gone back and forth with RK Drums in the past (Ron Kyle was a personal friend who has now passed away) and I disagree that it is cost prohibitive. It is actually pretty simple if the drum design is changed a little.

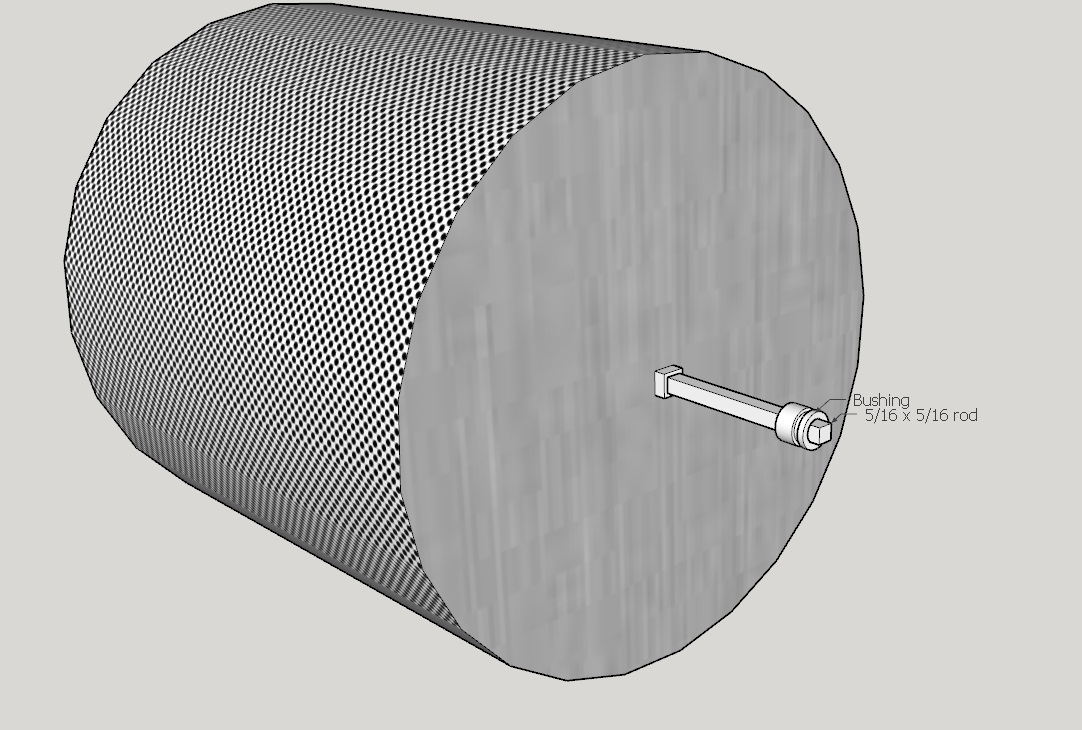

The RK Drum uses a 5/16” square rod stock to drive the drum with a carbon steel bushing for it to roll on. It looks like this.

It’s a pretty simple modification to weld a 3/4” square tube to the drum, add a 1/2” round tube inside and have a larger bushing. They would nest like this:

The final assembly would look like this.

I’m not sure what Shane was envisioning for $200 but I don’t think it was this. There is not a lot of reason you could not do this yourself or have a local shop do it and suddenly you have bean temperature.

As for the Behmor profiles, I’ve looked into this over the years and I hate to break it to you but it is a case of ‘lost in translation’. I have a lot of inside information. Those graphs you see are not power levels as we think of them (although the current model allows actual power levels in manual control. P4 in in manual mode (not the profile) is 80% power). I know they are labeled that way but they just are not power levels. They are percentages of the maximum temperature (which is unknown) the system is allowed to get to as read by the thermocouple on the side wall. As for your belief that the Behmor works because it calculates segments based on temperature and weight input isn’t true. The segments are all pre-programed empirically and are static. They work because the profiles were built specifically for each weight load and they work for cocoa because I worked out (again empirically) what load was needed (about 2 lbs) to roast correctly.

As for changing your gas flow off predictions, it sounds ok in theory, but in practice it fails horribly because you don’t have control of all your conditions. The biggest condition you don’t have control over is your ambient temperature. Just a 10 F difference in air temperature can change your needed BTU input by 10%. 15 F can make a 20% difference. And it isn’t linear nor predictable because you have other variables. Is it your first, second or third roast? Those have an effect too.

In the winter when it is 60 F in the warehouse I need to be 20% more gas on the first roast and subsequent roasts stay pretty constant. Currently (in summer) I’m 10% less than my average winter settings and 25% less after the 3rd roast because the room is so warm. And I only know this because I have direct bean temperature readings.

Also, don’t forget about wind. Moving air (convection) strips heat away from your grill horribly. I’ve seen a light breeze increase my roast times 50% and actual wind 80%. And without a bean temperature to tell you your how much your profile is running behind you don’t know whether to turn your burners up 50% or 80% or even at all.

Driving the point home (pun intended) could you drive your car up a hill with different areas of steepness without a speedometer or seeing the road go by and keep your speed exactly the same based solely on how much your are pressing on the gas? It’s incomprehensible, isn’t it?

Roasting blind in a drum and expecting to hit a specific profile is just as impossible.

I hope that helps illuminate why.