Level: Alchemist

Read time: 22 minutes

If we can roast cacao with our Diedrich IR12 that would solve everything. I only ran one small batch but it was a mess. 50% of the beans cracked to nibs and fell out of the drum on the inside. Had to dump the roast into a large bowl because we’d lose the nibs through the holes in the cooling tray. We did make chocolate from it and it was sour and bad. Any information you can give would be really appreciated.

Part of my Roasting Seminar (now that Covid is receding, we will have them again this year) is talking about how to use a classic drum coffee roaster for cocoa. I’ve also helped many people privately over the years set up their coffee roaster for cocoa. I’ve been wanting to answer this publicly for a while now so now is the perfect opportunity. So consider this a bit Alchemist rambling instruction, a touch P Chem lecture, a dash of historical fiction and a whole bunch of information that should give you everything you need to dial in a drum roaster for roasting cocoa.

Let’s set the stage. As I mentioned, this is a little historical fiction. The events really did happen. I absolutely helped someone with a Diedrich IR12 coffee roaster set it up for cocoa but some of the details are fuzzy, many of the calculations I did behind the scenes, and I am tweaking the quotes for the sake of clarity and the story. So there.

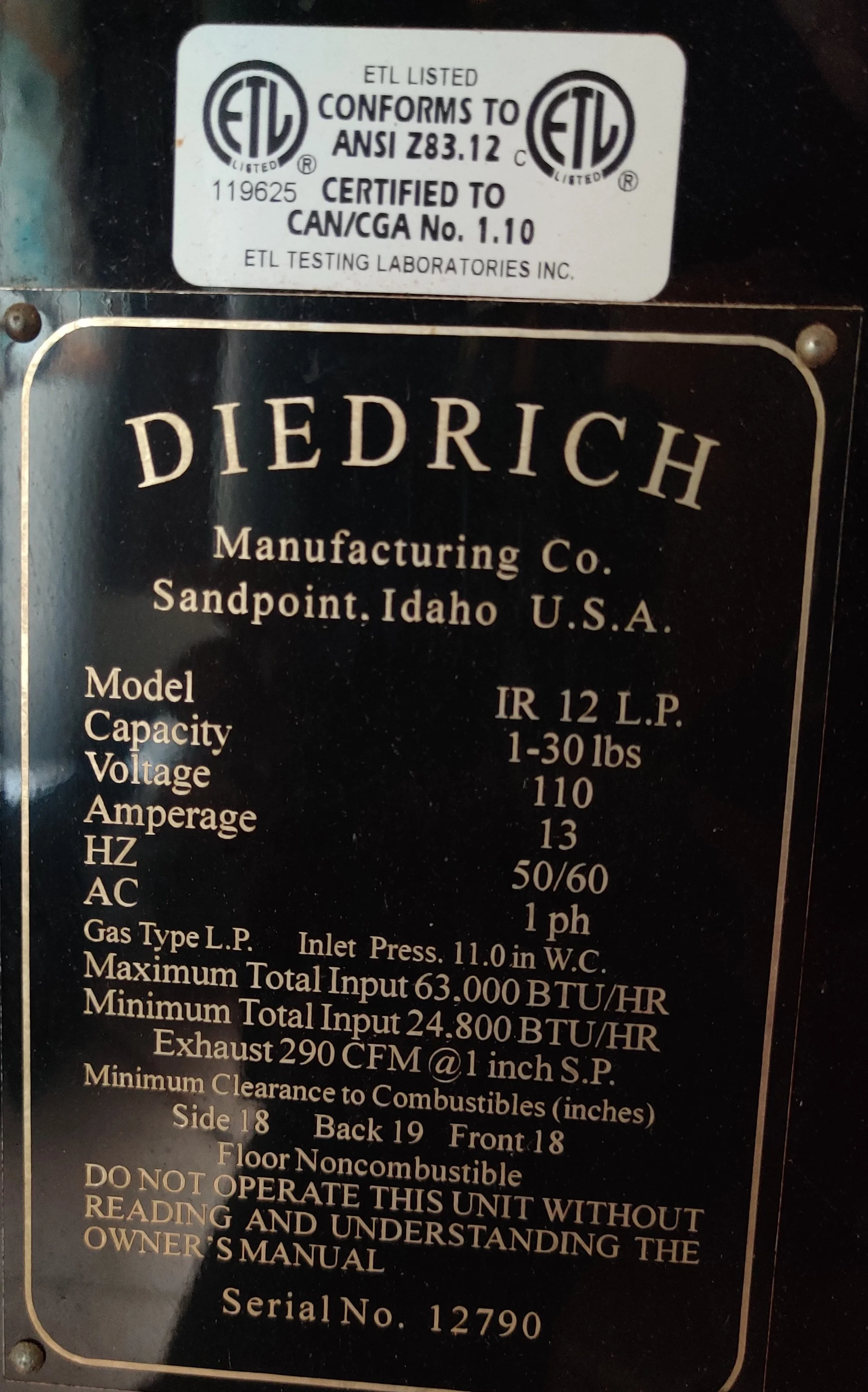

The roaster in question is a Diedrich IR12 and this is the specification plate on the roaster.

The important information to pull out of this is that the roaster has a range of 24,800 – 63,000 BTU/hour.

That is critical information. The other important piece that I had to ask the customer for was the dimensions of the drum.

I called Diedrich and they gave me the exact dimensions for the drum. My measurements were close, but less precise.

The drum length is 24.875"The drum inner diameter is 16.375"

With those two bits of information, and my experience doing this and roasting tens of thousands of pounds of cocoa on dozens of different roasters, we have what we need to do an initial batch and have a reasonably good chance of success. I say it that way as what I have learned is that this is not unlike the adage that a battle plan is only good until the first shot is fired and then you have to adapt to the reality of the situation. Ok, let’s jump in. I’m going to be tossing a bunch of data at you that I’ve collected over the years but I’m also going to leave some out as it will just muddy the waters.

The very first thing I know from experience is that nearly every coffee roaster out there should be loaded with about double the amount of cocoa. That specification plate says up to 30 lb of coffee. That tells me we are in the ballpark of 60 lb of cocoa. But we can do much better than that but it is a really good check on our calculations.

You need about 425 BTU per pound assuming you are going from an ambient room temperature of 70 F to an EOR (end of roast) temperature of 250 F.

From that you can derive a more general amount of energy needed since you know you went up 180 F (250-70 = 180)

425 / 180 = 2.36 BTU/lb/F for cocoa beans. But that is for fine tuning. For now we can just check how many beans we can roast with the available energy of the roaster.

We have up to 63,000 BTU/hour available. Note that is per hour. I use a benchmark roast time of 20 minutes or 1/3 of an hour. That means we have one third of 63,000 BTU or 21,000 BTU available. A little quick division tells up the most we can roast.

21,000 / 425 = 49.4 lb cocoa. (Guideline #1)

Is that close to the 60 lb prediction? Yep, it sure is. And how small of a batch could you do without fear of being totally out of control? One third of the low end of the burners (24,800) is 8267 BTU

2867 / 425 = 19.5 lb (Guideline #2)

So now we have our range….and that got me thinking about what the customer tried at first, so I asked them how they roasted and they gave me this….profile…and I say it like that as it was not so much a profile as the conditions they used, but close enough.

The very first thing that jumped out at me is that they tried to convert oven setting to drum roasting. Let me say this VERY CLEARLY.

You

Can

Not

Do

That

Yep, I am an oven roasting bigot. And like all bigots I’m going to justify it because I think I’m right. It isn’t that I don’t like chocolate from oven roasting, it is because of stuff like this. People seem to think if you roasted baked your beans at 250 F for 45 F in an oven you should do the same in a drum roaster is so far from reality, no wonder people get frustrated. In reality you want to go the other direction. It would be great if you could profile roast in an oven, getting to your EOR temperature in 15-20 minutes, but the reality of the physics and temperature gradients is that if you try, you end up scorching the surface of the bean in contact with the tray and under roasting edges that are touching. I ramble all about there in ATA #202 (https://chocolatealchemy.com/blog/2017/4/20/ask-the-alchemist-202). The solution that most people eventually find that is the most reproducible is, to use the colloquial term, ‘long and low’, or 45-60 minutes at a temperature that doesn’t damage the beans but gets them up to a reasonable EOR temperature in semi-reasonable time. My point here is that drum roasting addresses that issue by tumbling the beans so there is no reason to try to match an inferior method of roasting.

So what went wrong? Have you caught it? They roasted 6 lb of cocoa….on a roaster that should not take less than 20 lb. No wonder the beans shattered and the chocolate was sour and hideous. They over roasted the hell out of it and thrashed it to pieces as there was not enough in there to self cushion. Here is the thing about many commercial coffee roasters. Coffee is durable - way more so than cocoa. The vanes inside the drum are specifically designed to loft the beans and toss them around so you get an even roast. Likewise, most are designed to use the maximum speed they can and not pin the coffee to the interior of the drum like some of those really fun carnival rides. Unfortunately, those conditions are not great for cocoa. I like a drum speed of 60 rpm for coffee but 45 rpm seems better for cocoa. Since it is generally not easy to slow down a drum motor (some do have this feature, so use it if you have it) the other option is to load the drum extra full compared to coffee….and oh, look at that, that is what I’m suggesting anyway. It is like a perfect alignment of the stars!!

With only 6 lb of cocoa in there, the beans were being tossed across the drum with so much energy that the beans were breaking. (Side note, there is a style of cocoa breaker that does this exactly. It flings the beans against a steel plate to crack them.) Notice also that they had to keep turning off the heat entirely because the temperature was reading too hot? That is precisely what you would expect since they should have at least 20 lb in there.

Just to make sure you have the information, there are two other things that were going on here. One is that temperature readings are only as good as how you take them. With only 6 lb in there, the probe was mostly reading air temperature and one of the many good reasons to roast in a drum roaster is that when loaded properly (see Guideline #1 & #2) the probe will be buried in the bean mass giving you an accurate bean temperature.

And that is Guideline #3. Make sure the probe is situated in the bean mass.

Generally speaking, for a clockwise rotating drum, that is usually around the 8-9 o’clock position and where you will find nearly all of them. If you load the minimum amount recommended (Guideline #2) and find the probe is not covered, you need to increase your load to that minimum. This is the case for my Royal #5. I can turn the burners down to roast about 10 lb of beans except the thermometer tip is sitting in air and my temperature readings are way way off (high), reading the hot air, not the beans. For that reason, my range is 25 – 35 lb.

The probe position for the Diedrich IR 12 is at the 8 oclock position and 20 lb covers it nicely.

The last cursory look over their conditions I noted they pre-heated to 375 F. In some cases this would be ok, and really one of those things that you note the behavior of the roaster and how it controls and modify your starting conditions in subsequent roasts. Based on previous experience I have found most commercial coffee roasters are insulated really well and you don’t need that much pre-heating. 325 – 350 F is usually fine and given the amount of available energy, I would lean toward the lower end if not even lower. I’ve started as low as 300 F.

Alright, one last thing before I offer up conditions for that first properly tuned roast.

Guideline #4 Drum Capacity

We know from an energy perspective 20-50 lb is the range for this roaster, but that is kind of wide. I mentioned we don’t want to thrash the beans around and that usually means you want the drum at least half full and 2/3 is often better. You don’t want to go over 3/4 full.

As a reminder we were given this.

The drum length is 24.875"

The drum inner diameter is 16.375"

Using the equation for a cylinder PI x radius squared x length we find the volume is

3.14 x (16.375 / 2) ^ 2 x 24.875 = 5236 cubic inches.

I know a 12”x12”x12” box is 1728 cubic inches and weights about 30 lb.

Fully packed that means the drum could hold:

5236 / 1728 = 3

3 x 30 lb = 90 lb of cocoa. Now, that is FULL. We want it 50 – 66% full so that means 45 - 60 lb.

And again, what do you know, the upper end is what the predicted high should be (based of the 2x coffee rule of thumb) and now we have a lower limit of 45 lb instead of 20 lb and confirmation that the drum can handle the 50 lb load the energy allows us to roast.

With that, we can set up the conditions based on our 4 Guidelines for our first roast and have a reasonable chance of success.

Guideline #1 Determine the maximum roast size based on energy. (Max BTU/hr) / 3 / 425

· Guideline #2 Determine the minimum roast size based on energy. (Min BTU/hr) / 3 / 425

Guideline #3 Refine Minimum capacity based on thermocouple placement

· Guideline #4 Determine capacity based on drum size. 50% - 66% full

· Start with the minimum weight that satisfies all conditions:

· #1 50 lb

· #2 20 lb

· #3 20 lb

· #4 45 – 60 lb

From that we can see the narrowest band is a load between 45 lb (Guideline #4) and 50 lb (Guideline #1). Keeping in mind that modern, commercial coffee roasters are well insulated, I recommend starting very conservatively on both the pre-heat temperature and initial fuel level.

325 F is a really fine pre-heat temperature for first roast.

Since the roaster can in theory do 20-50 lb from a heat perspective and I’m suggesting 45 lb, I would set the burners at about 90% (45 / 50 = 90%) and then take off another 15% just to be safe, so about 75% or about 63,000 BTU/hr x 75% = 47,250 BTU/hour. Most likely there is not a way to control it by BTU/hour but most roasters have some type of flow gauge and you can use that. Purely making up numbers, if full power is 32 cubic feet per hour, then 32 x 75% would be about 24 cfph.

And with all those calculations done, that is what I suggested. I also gave these rough benchmarks.

For this first roast, shoot for roasting by the numbers. My token goals on an initial roast are 9-12 minutes to get to 212 F, 2-3 minutes to go another 20 F to 232 F, and 3-5 minutes after that to reach the end of roast (EOR) in the mid to high 250s, stopping the roast when I note it getting sharp or acrid. Beans may or may not pop like coffee and ROUGHLY, if they do, you often have another 2-3 minutes to go, but that can be pretty variable depending upon moisture. If you want to dive into where and why I suggest those numbers, I have all that laid out in detail in Ask the Alchemist 200-206

They were understandably a little nervous about loading up nearly 8 times what they previously ruined, but understood where I was coming from why the previous roast failed. They had

· Too much heat

· Pre-heat/charge temperature too hot

· Not enough load to get a real temperature reading

· Too little load to self cushion)

With all that in hand they went for it….to basically great success.

I completed the roast after our daily coffee roasts. In our machine with the burners around 75%, the temperature started climbing too quickly so I adjusted the burners down to around 15% after I was 4 minutes into the roast to slow it down. The hot start (we had just finished roasting coffee) had me hit all the marks slightly ahead of time. For example, I was at around 212 at just a little under 8 minutes in. Next time I will start the gas around 20%, and I feel like I will be closer to your profile. At round 8 minutes in I lowered the burners to their minimum and was able to get the 259 by 15 minutes. Basically I spent too little time in what you call the drying/momentum phase, and too much time in the development phase. See attached profile.

All of the beans were in great shape though, so that was a big success! Thank you for the help!

Their control reading (75%) ended up bringing up a characteristic I had not encountered before and that is relative vs absolute burner control. I followed up with the customer with this:

When I recommended 75%, I meant 75% of the top output possible. It appears that Diedrich controls through percentages of relative output and when doing your own calculations, you absolutely have to take that into account. This is what I mean and what went wrong.

75% of the top end of 63,000 is 47,000 BTU (I’m dropping some of the units here for readability)

The big catch here is that the range is 24,800 to 63,000 or 39,200 BTU so when they set the burners at 75% it was 75% of 39,200 plus the minimum.

75% x 39,200 + 24,800 = 54,200.

That ends up being (54,200 / 63,000) 86% absolute burner power. Coupling that with doing the cocoa roast after a coffee roast, that completely explains why the roast proceeded way faster than expected. We have seen this ourselves when we do really hot roasts for brewing cocoa that are in the range of 350-400 F EOR. The roaster ends up acting as a heat sink and giving that energy back in the next roast, so although the roaster might read a 350 F open air temperature, the walls and drum are really well over 450 F.

When you mention 75% power to the burners, do you know if that is 75% absolute or relative? I meant absolute but since your burners have a minimum power, I wondered if you set it to relative. In either case it seems you handled it just fine and it is worth noting the drying phase isn't that important except to hit the Development phase correctly, which you did.

I continued with some of the calculations I previously went over in greater detail above.

To give you a benchmark calculation, I use 425 BTU/lb for the roast profile length and EOR I give. So for your load of 45 lb, that means about 17K BTU. Since the target is about 20 minutes (1/3 of an hour) that would put your burners at 17x3 = 51,000 BTU. Given your burners can go to 63 KBTU/hour, that is why I said about 75% (I see the calculation actually puts that at about 80%). Going back to the relative vs absolute thing, if you went relative at 75%, 63,000 - 24,800 = 38,200. Adding 75% of that to your low end (24800 + 26500) gives you 53,450 BTU/hour which might not sound like much, but might be why your roast went quick. (Note to readers, I know these are not the exact numbers I have above but you can see they are close – I was spit balling for the customer)

I know that is a lot but I think that gives you everything you need to know about using a coffee roaster for cocoa. There are a few other details that I just want to touch on that often come up.

Seeing how the roaster behaved on this first roast, I would totally be comfortable increasing the load beyond the 50 lb estimate of Guideline #1….it is just a guideline. There is every possibility the roaster was outputting way more than the plate stated (63,000 BTU/hour). For all we know it is well over 70K BTU/hour. The entire point is that you adjust for your conditions after the first roast.

Like so much of chocolate making, and really anything you make, or build, or create, it is all about doing it once, learning from it and doing it again, tweaking it here and there until it is to your liking. In other words, you iterate. Learning how to roast on a roaster is absolutely no different. And that really leads us to the Golden Guideline.

Golden Guideline: Iterate: Do it, learn, do it again…..and repeat those steps…until you are satisfied.

Ok, there are a few more items that just didn’t fit into all the ramblings above.

I am convinced you can roast coffee and cocoa on the same machine and there is no cross contamination in either direction. Coffee can build up a surface on the drum but it won’t transfer to cocoa and cocoa won’t make your drum oily with cocoa butter. I’m not going to bother deeply explaining why this is the case at this point. Maybe I will at some point. Just know I’ve done it for nearly 2 decades and no one has ever come back to me with an issue.

You may or may not need to do thermal cleanouts after roasting cocoa for the sake of the exhaust systems. I’ve heard from some people that roast coffee, there is extra build up in the exhaust system after multiple cocoa roasts, in comparison to coffee. To them I recommend a 500 F dry burn to thermally clean out the exhaust system at the end of cocoa roast system, before going back to coffee. We personally don’t do this but we do a thermal cleanout routinely as we switch between Organic and non-organic beans, i.e. we take the roaster up to over 470 F. By doing that we don’t seem to have any additional exhaust buildups. So it is not so much as a decontamination step as a preventative maintenance one.

Coffee roasters often have air flowing through the drum and in some circumstances the flow can be so high (100 exchanges per minute) that some of the more delicate aromatics can get stripped from cocoa. If you have the option, close the flow down as much as possible. I like to try and keep it to 10 exchanges or less. And what I mean by exchanges are drum volume. In the roaster above, the drum is about 5200 cubic inches or 3 cubic feet. That means I’d prefer to keep the air flow through the drum to 30 cubic feet or less. If is more than that, it is not the end of the world and I suggest you go by empirical data. Do a roast or two and determine if you like the resulting chocolate. If you do, don’t bother trying to fix what isn’t broken.

And that leads me to my final point. To date I’ve not found a fluid bed air roaster that roasts cocoa like I want. The air flow is so high working to keep the beans aloft, that a lot of flavor and aroma is stripped away. Add in that due to cocoa’s larger surface area, it is even more difficult to fluidize (float) cocoa in an air stream, you ended up being able to roast less cocoa instead of more as you can in a drum roaster.

There! I think I’ve laid it all out for those of you that want to dig deep. If it is too much, I’m always happy to help. Just drop me an email and I’m there for you. And if you want this in person, now that Covid shows that it might be waning, I’ll be offering in depth, full day Roasting Seminars where I go over all this and more.

At the end of the day, we come back to this about chocolate making, learning and really life itself.

Golden Guideline: Iterate: Do it, learn, do it again…..and repeat those steps…until you are satisfied.

Happy roasting everyone.